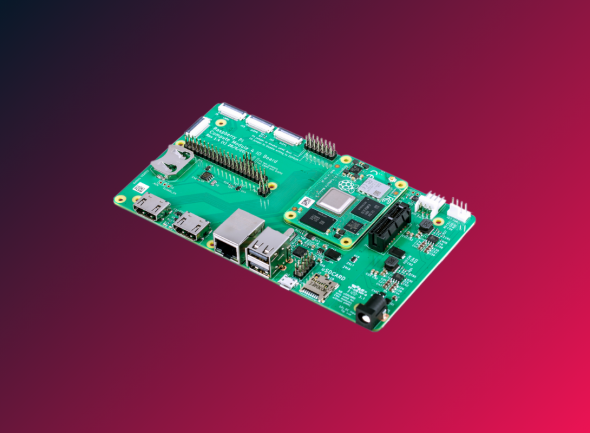

NEW EXTENDED TEMPERATURE RANGE FOR RASPBERRY PI COMPUTE MODULE 4

19. January 2026 | Planegg

Many Raspberry Pi–based systems run unattended for years in industrial and embedded applications. Astradis translates this operating reality into auditable platform requirements: defined temperature limits, clear variant identification, traceable BOM governance, and predictable availability across series production and service life.

Compute Module 4 was previously specified with a minimum operating temperature of -20 °C. Raspberry Pi now introduces variants with an extended operating temperature range of -40 °C to +85 °C. For OEMs, this means cold start and continuous operation in colder environments can be planned precisely within a documented specification. In day-to-day projects, this supports audits and documentation (requirements, acceptance criteria, test plans, environmental qualification) and secures the decision on whether CM4 remains suitable as a platform for cold/outdoor sites or whether a platform change would be required.

Raspberry Pi enables the extended range through extended-temperature SDRAM and eMMC components from Samsung, while other components were already qualified for the wider temperature range. For series release and risk assessment, the decisive point is which components vary and how these variants are governed unambiguously in the BOM, change management, and spare-parts strategy. In projects, this reduces failure-proneness across procurement and quality processes (variant control, evidence packages, re-validation) and supports the decision on which exact configuration is frozen and qualified as the series standard.

The variants are available with and without wireless connectivity, and with different RAM and eMMC configurations. For OEMs, this means connectivity and memory requirements can be implemented as controlled platform variants instead of ad-hoc design deviations. In projects, this supports scaling and series execution (SKU definition, test coverage, serviceability). It secures the decision on which core variants remain stable across lifecycle and supply chain.

Standard variants are available from us as an Approved Reseller; additional variants are built-to-order with a minimum order quantity. > Request here

Benefits

- Extended temperature range: -40 °C to +85 °C, for extreme indoor and outdoor environments

- Variant choice: with and without wireless, with different RAM and eMMC options

- Planning reliability through clearly defined availability, partly from stock, partly built-to-order with MOQ

- According to the product brief, CM4 will remain in production until at least January 2034

Astradis Elektronik enables an audit-ready platform decision: we derive variant and sourcing requirements, translate the temperature specification into qualification and acceptance criteria, and secure decisions through documentable evidence (specification, variant identifiers, BOM status, sourcing model). If built-to-order is relevant, we also structure planning around MOQ and lead time.

Contact us for further information and an individual consultation.

FAQ

Which applications are the extended temperature variants intended for?

For systems that must start and operate reliably below -20 °C, for example, outdoor installations, infrastructure, logistics, energy, and industrial sensing.

Which variants are available the fastest?

A core selection is available; additional variants are built-to-order with a minimum order quantity.

What should I consider for planning and sourcing?

For built-to-order, a minimum order quantity of 1,000 units and a typical lead time of 10 to 12 weeks are planned. For specific availability and options, please contact us: ANFRAGE